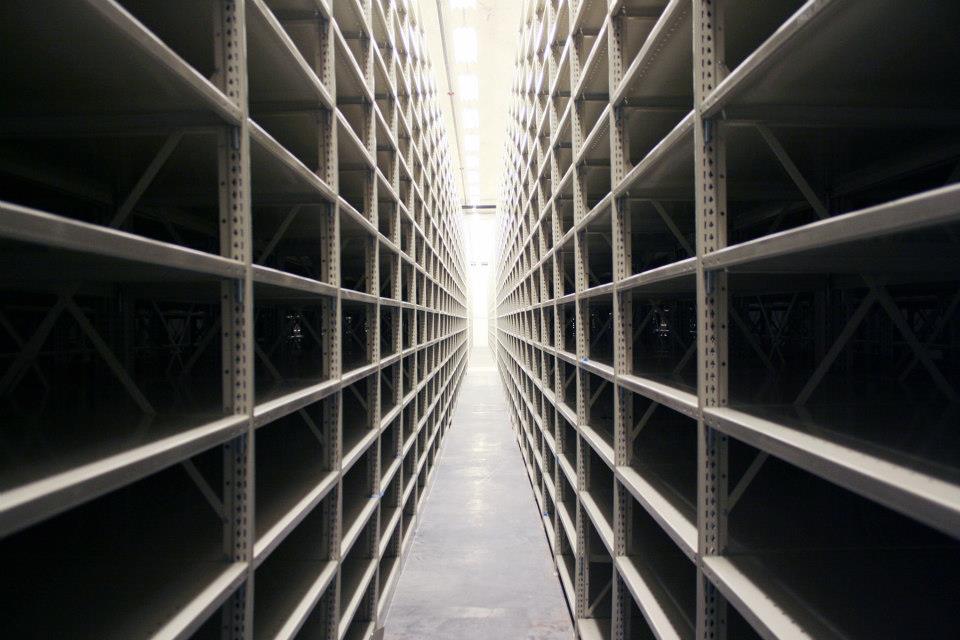

Clipper® - Industrial Shelving

Clipper Shelving features Hi-Performance® Box Beam Shelves, which offer an exceptional strength-to-weight ratio for industrial settings. Clipper Shelving offers a wide variety of sizes and capacities too. This gives you the flexibility to provide top quality storage for a simple back room area, up to a sophisticated multi-level or high-rise application.

At the heart of the Clipper® Shelving System is the ingenious Penco Clipper Clip. It is easily installed, holds the shelf firmly in place, can be repositioned at any time, and actually helps make the shelving more rigid.

Clipper open type shelving is the basic and most economical shelving design for general purpose use. Backs and sides are open with sections stabilized by sway braces. Closed type shelving units are covered on three sides with steel panels to provide stability, protection and to promote cleanliness of stored items. Optional locking doors may be added for greater security.

CLIPPER® Shelving features the same Hi-Performance Box Beam Shelves as used in ERECTOMATIC® shelving. These are produced on a state-of-the-art production line that begins with a flat steel blank and ends with a completed shelf. For additional strength, flanges of the box beams are welded to the underside of the shelf on 3" centers, shelf corners are lapped and welded and sides are double flanged.

Shelves are available in a wide variety of sizes and 24 baked enamel colors. All shelves are punched on the face and surface to accept accessories. Shelves are available in three main capacity ranges: Medium, Heavy Duty and Extra Heavy Duty. Each shelf comes with four compression shelf clips

OFFSET ANGLE: Offset angle post shall be roll formed and have overall dimensions of 1-1/8" wide x 2-1/2" deep. The rear flange shall be punched to accept sway braces or backs, the side flange shall be punched to accept side sway braces or side panels.

GENERAL: All shelving shall comply with SMA and ANSI MH 28.1-1982 and in addition shall have the following characteristics:

POSTS: All posts shall be punched for clip or nut and bolt construction. Shelves and accessories are to be vertically adjustable on 1" centers. Side sway braces or side panels to be attached to the side flange of the post. Bolts, nuts, and sway braces or panels shall not obstruct the full adjustability of the shelves.

BOX POST: Box post to be roll formed and have overall dimensions of 3/4" wide x 2-7/16" deep. Box post to be flush within 1/4" of the face of the shelves when assembled.

SIDE PANELS: Shall be 24 gauge steel. Each side shall be punched with holes for bolting to posts.

BACKS: Shall be 24 gauge steel with holes on each side for bolting to angle posts and in the middle for using a back panel clip.

SWAY BRACES: To be 12 gauge x 3/4" steel punched at each end for bolting to posts and at the center for strength and ease of assembly

CLIPPER SHELF CLIP: One piece 14 gauge rugged compression type to insert into either box or offset angle posts to form a positive four point connection. Clips shall have two claw-like hooks to seat firmly into post slots and two tabs at bottom to seat into post holes for a tight friction connection. All clips for all posts and shelves to be the same. Design shall offer a pre-clipping feature to simplify erection. Finish: zinc plated. All shelves are to have four independently adjustable clips.

SHELVES: CONVENTIONAL FLANGE: Shall be 18 gauge steel with a 1-3/16" vertical face on all four sides, front and rear faces to have 17/32" return flange 90_ with the edges coined upward to prevent snagging. Sides to have a 5/8" return flange 90 . All four shelf corners shall be closed by lapping and spot welding together to provide a firm, rigid shelf. Shelf shall be universally punched for use with all available accessories and for clip or bolted assembly. Shelves are available in 24", 30", 36", 42" and 48" widths and 9", 12", 15", 18", 24", 30" and 36" depths. Shelves can be reinforced by adding 1-3/32" x 11 ga. bars or 1" x 1" x 1/8" angles to front and back flanges.

SHELVES: CLIPPER HI-PERFORMANCE BOX FORMED: Medium Duty, Heavy Duty and Extra Heavy Duty are manufactured from cold rolled steel in three material thicknesses that provide up to three different shelf capacities per size. Shelves have 1-1/4" face on all four sides. Front and rear faces have four 90_ bends providing a 3/4" x 1-1/4" high tubular shape with an 11/16" wide flange seated against the underside of the shelf. The flange is spot welded to the underside of the shelf on 3" centers. Sides have a 5/8" return flange 90_. All four corners are closed by lapping and spot welding together. Medium Duty and Heavy Duty shelf tabs for lapping and welding have formed ribs to maintain the same snug fit in the shelf clip as the extra heavy duty shelf. Overall, the shelf depth and width is 1/4" less than nominal. The shelf is punched for divider adjustment on 1-1/2" centers and for attachment of label holders, bin fronts and base fronts. Hi-Performance shelves are available in 36", 42", & 48" widths and 12", 15", 18", 24", 30" & 36" depths.

Extra Heavy Duty Reinforced (Class 3) Hi-Performance Shelves provide maximum capacity using Extra Heavy Duty shelves that are reinforced using 13 gauge side shelf supports bolted to the Clipper posts and 14 gauge 1-5/32" high hat shaped center supports held in place by a notch and flange in the side shelf support.

LEDGE TOPS: To be 14 gauge steel. Face of ledge to be 1-1/8" and have a center reinforcing pan. Ledge top to project 1-1/8" beyond the face of the post and to have two 14 gauge angles welded to underside for strength and bolting to post. Must be used with box posts below ledge.

LEDGE ENDS: To be manufactured from 14 gauge steel and furnished to give ledge top a finished appearance.

COUNTER TOPS: To be 14 gauge steel. Face of counter top to be 1-1/8" and project 1-1/8" beyond face of post with a welded center reinforcing pan. Units to be furnished with box post front and rear for finished appearance. 14 gauge counter top ends can be furnished at the ends of all rows for a finished appearance.

COUNTER FRONT: To be 18 gauge steel attached with no exposed fasteners.

BASE STRIP: Shall be 18 gauge steel attached to face of shelf with bolts and nuts to close space between the bottom of the shelf and the floor.

LABEL HOLDER: Shall be 24 gauge steel with necessary holes for attaching to shelves with plastic push-in fasteners.

SHELF DIVIDERS: 6" high through 20" high shall be 24 gauge, 24" high and over shall be 20 gauge. All divider front flanges shall have a 5/16" diameter bead. Top, bottom and rear flanges are 7/8". Dividers less than 24" high shall be attached with plastic push-in fasteners, 24" and higher are bolted.

PARTIAL DIVIDERS: Shall be 18 gauge steel with a 7/8" flange at the bottom. Attached with push-in Plastic Button fasteners.

SLIDING DIVIDER: To be 20 gauge steel manufactured to give infinite lateral adjustability. Divider portion shall be sloped 45_ at front, 1/2" radius at front corner.

BIN FRONTS: To be 18 gauge steel. One and two inch high bin fronts shall be bolted to the face of the shelf. Three inch high bin fronts to be attached to the post by use of 16 gauge zinc plated channel clips.

SHELF BOXES: To be 20 gauge steel with a rigid curled handle at the front of the box, punched with an integral card holder on front and rear. Box shall be 4-5/8 " high to fit between shelves on 6" centers and shall be slotted to accept dividers on 1" centers.

SHELF BOX DIVIDERS: To be 20 gauge steel. Punched with an integral card holder.

SWINGING DOORS: Consist of a 16 gauge steel frame and 20 gauge doors, reinforced to prevent warping. Doors are riveted to three 5-knuckle hinges and have a three-point latching device with chrome plated key lock handle. Doors to be preassembled in the frame at factory.

SLIDING DOORS: Set of doors is 72" wide and cover two 36" wide units. Each door shall be 22 gauge with two or more 18 gauge reinforcing pans, recessed handle and nylon glides and rollers. Each set has 16 gauge channels welded at the top and bottom, and 20 gauge channels on the ends. Doors shall be contained in top, bottom and vertical channels. Right hand door has a provision for a cylinder lock.

FOOT PLATES: Shall be 13 gauge zinc plated steel and be used to protect floors.

FINISH: All painted parts shall be selected from a minimum of four standard colors. Materials shall be cleaned and phosphatized in a multi-stage process, dried in a 400 degrees oven and electrostatically spray painted with a high grade enamel and baked on at 360 degrees.

| Color Number | Color Name | Color |

|---|---|---|

| 054 | Canvas | |

| 021 | Gray Ash | |

| 028 | Gray | |

| 073 | Champagne | |

| 723 | Light Putty | |

| 012 | Tawny Tan | |

| 701 | Spray Green | |

| 952 | Turquoise Teal | |

| 055 | Shamrock | |

| 812 | Hunter Green | |

| 715 | Lake Blue | |

| 823 | Slate Blue | |

| 806 | Marine Blue | |

| 052 | Reflex Blue | |

| 822 | Regal Blue | |

| 058 | Nordic Purple | |

| 056 | Sunburst | |

| 710 | Sagebrush Yellow | |

| 720 | Mandarin Orange | |

| 722 | Patriot Red | |

| 767 | Cardinal Red | |

| 736 | Burgundy | |

| 848 | January White | |

| 949 | Jet Black |

NOTE: Colors shown are as close to actual finishes as the printing process allows. Do not make your final color selection based on the color shade shown on this page. Penco Color Charts are available for a more accurate color match. Exposure to high humidity, chlorine salts, abrasive cleaners, germicidal cleaners and acids can damage the finish and will void the guarantee. For outdoor applications or other harsh environmental conditions, contact your Penco Representative.

View Our Configurator

Our configurator allows you to find a Penco product to meet your specific needs.

Start Now